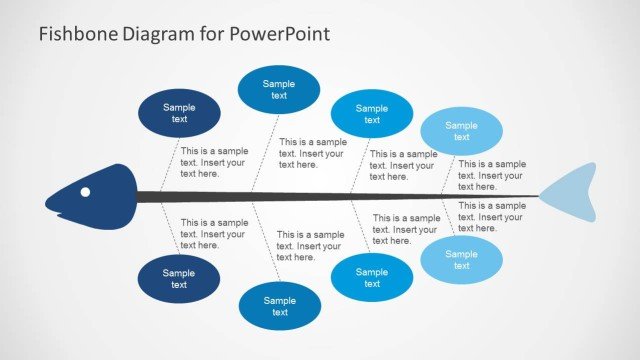

Strangely this tool has three commonly used names. It allows you to identify, explore and display a problem and all the possible causes in a structured way. The purpose of a cause and effect diagram is to gather information and ideas from as many people as possible and to explore all possible causes of a problem. It's a formal brainstorming tool for identifying possible root causes. The cause and effect diagram was created by Kaoru Ishikawa in the 1960s.

#Ishikawa diagram in six sigma professional#

Also, it is a highly-recommended text for those wishing to move forward in Six Sigma and eventually gain certification from professional agencies such as American Society for Quality (ASQ). However, the text is a recognized handbook used by professionals in the field. The companion text is NOT required to complete the assignments.

#Ishikawa diagram in six sigma registration#

Registration includes online access to course content, projects, and resources but does not include the companion text The Certified Six Sigma Green Belt Handbook (2nd edition).

You will also have the opportunity to participate in discussions and peer review exercises to give you the opportunity to apply the material to your daily life. This course will provide you with the basic knowledge of the principles, roles, and responsibilities of Six Sigma and Lean.Įvery module will include readings, videos, and a quiz to help make sure you understand the material and concepts that are studied. Your instructors will introduce you to, and have you apply, some of the tools and metrics that are critical components of Six Sigma. You will learn about the basic principles of Six Sigma and Lean. This course will introduce you to the purpose of Six Sigma and its value to an organization. These skills have been proven to help improve business processes and performance. Six Sigma skills are widely sought by employers both nationally and internationally. When a process is not predictable (out of control), Fishbone can identify areas for continuous improvement by removing non-value added activities to create a more stable process.This course is for you if you are looking to dive deeper into Six Sigma or strengthen and expand your knowledge of the basic components of green belt level of Six Sigma and Lean. When a process is predictable (in control), the Fishbone diagram will assist in identifying continuous improvement opportunities for a better process.

Continue to sub-divide all the causes for each branch until all causes are included. Decide on principle causes and show these as the major branches of the horizontal arrow.

0 kommentar(er)

0 kommentar(er)